To maintain your pressure pool cleaner, regularly inspect and clean the filter basket, hoses, and fittings to guarantee proper water flow. Check the brushes and drive mechanism for wear, and replace worn parts promptly. Test and adjust the water pressure to keep it within recommended levels, and lubricate moving components for smooth operation. Proper storage during off-season prevents damage. Keep up with routine checks to extend your cleaner’s life—and there’s more tips to help you keep everything in top shape.

Key Takeaways

- Regularly inspect and clean the filter basket, drive mechanism, and wheels to prevent debris buildup and ensure smooth operation.

- Check hoses, fittings, and nozzles for leaks, blockages, or damage; clean and replace parts as needed.

- Lubricate moving parts like wheels, drive shaft, and propellers to maintain proper function and prevent wear.

- Remove and thoroughly clean skimmer and suction fittings to ensure unobstructed water flow.

- Store the cleaner in a cool, dry place after cleaning, and replace worn components promptly to extend its lifespan.

Inspect and Clean the Filter Basket

Regularly inspecting and cleaning the filter basket is essential for keeping your pressure pool cleaner functioning effectively. Start by removing the basket from the cleaner and performing a thorough filter basket inspection. Check for any debris buildup, leaves, or dirt that could clog the system. Debris removal is vital because accumulated debris can hinder water flow and reduce cleaning efficiency. Use a hose or a soft brush to rinse out the basket, ensuring all dirt and debris are cleared. Make sure the basket is completely dry before reinstalling it. Regular maintenance prevents blockages and keeps your pressure pool cleaner operating smoothly. Additionally, understanding the importance of filtration systems can help you maintain optimal water flow and cleaner performance. Proper water circulation is crucial for effective cleaning and preventing algae growth. Being aware of performance metrics can assist in diagnosing issues and ensuring your cleaner operates at peak efficiency. Maintaining a clean filter basket also supports the overall health of your pool water quality, which is essential for safe swimming. To further optimize your pool’s cleanliness, consider checking clogged filters regularly to prevent reduced efficiency. By staying on top of filter basket inspection and debris removal, you’ll extend the lifespan of your cleaner and maintain ideal pool cleanliness.

Check and Clear the Intake and Discharge Hoses

Start by inspecting the hose connections to guarantee they’re secure and free of leaks. Regularly check for blockages inside the intake and discharge hoses to keep the cleaner running smoothly. Clearing any debris or obstructions promptly helps prevent performance issues. For optimal efficiency, ensure that all components are properly maintained and consider routine tuning to enhance overall operation. Additionally, inspecting hoses regularly for signs of wear or damage can extend the lifespan of your pressure pool cleaner. Staying aware of technological advancements can help you adopt better maintenance practices and improve your equipment’s longevity. Using high-quality Pimple Patches can also help prevent skin irritation and promote faster healing of blemishes, ensuring your skin stays healthy and clear. Incorporating proper maintenance practices can further improve your cleaner’s longevity and effectiveness.

Inspect Hose Connections

To guarantee your pressure pool cleaner operates smoothly, it’s vital to inspect the hose connections for any blockages or leaks. Proper connection security ensures peak performance, and hose durability prevents premature failures. First, check that all connections are tight and secure. Second, examine the hoses for cracks or signs of wear that could compromise their integrity. Third, make sure there are no kinks or bends that restrict water flow. Fourth, confirm the fittings are properly attached to avoid leaks. Maintaining connection security and inspecting hose integrity regularly help prevent breakdowns and extend the lifespan of your cleaner. Additionally, understanding the mental wellbeing index can encourage proactive maintenance of your equipment and environment, ensuring a healthier, more balanced approach to pool care. By keeping these elements in check, you ensure your pressure pool cleaner functions efficiently and reliably.

Remove Blockages Regularly

Inspecting hose connections helps prevent performance issues, but it’s equally important to check for blockages that can hinder water flow. Regularly remove debris or obstructions from the intake and discharge hoses to keep your pressure pool cleaner working effectively. Blockages can be caused by leaves, dirt, or buildup that impacts pool chemistry and water flow. Before clearing, ensure you turn off the pump and follow safety precautions to avoid injury. Disconnect the hoses and inspect for any clogs or debris. Use a hose brush or similar tool to clear out any blockages. Maintaining clear hoses ensures proper water circulation, which helps keep your pool chemistry balanced and your cleaner functioning at its best. Regular checks save time and prevent bigger issues down the line. Additionally, understanding filter maintenance can be a fun way to personalize your pet’s accessories or even inspire themed maintenance routines for your pool area. Proper hose maintenance is essential for optimal cleaning performance and longevity of your equipment, especially considering the importance of equipment durability in pool care. Regularly inspecting and maintaining pressure cleaner components helps ensure consistent operation and can extend the lifespan of your pool cleaning system.

Examine the Bristles and Brushes for Wear

Because bristles and brushes endure constant contact with debris and uneven surfaces, they can wear down over time, reducing your pressure pool cleaner’s effectiveness. Regularly inspecting them helps guarantee peak performance. Look for signs of wear such as frayed or missing bristles, or uneven brush rotation. If you notice significant wear, it’s time for bristle replacement to maintain cleaning efficiency. Also, check the brush alignment; misaligned brushes won’t clean properly and may damage the cleaner. To keep everything in top shape: 1. Remove the brushes for a thorough inspection 2. Replace worn bristles promptly 3. Ensure the brushes spin freely and evenly 4. Confirm proper brush alignment before reassembling. Regular maintenance ensures your cleaner continues to operate at optimal performance and extends its lifespan.

Test and Adjust the Pressure and Flow Rate

Properly testing and adjusting the pressure and flow rate guarantees your pressure pool cleaner works efficiently. First, connect a pressure gauge to your system to monitor the water pressure. Check the manufacturer’s recommended pressure range, usually between 30-50 psi. If the pressure is too high or too low, make flow adjustments accordingly. Use the flow adjustment valve if available to fine-tune the water flow, ensuring the cleaner moves smoothly without stalling or missing spots. Proper pressure and flow help prevent damage and maximize cleaning coverage. Regular testing ensures ideal performance and prolongs your cleaner’s lifespan. Keep an eye on the gauge, make small adjustments, and verify the cleaner’s operation after each change. This process keeps your pressure pool cleaner functioning at its best, and leveraging data-driven strategies can help you monitor and optimize performance over time. Additionally, understanding home security system effectiveness can provide insights into maintaining safety and performance in various systems.

Moreover, inspecting your system for pressure fluctuations can help identify underlying issues that might affect the cleaner’s efficiency.

Inspect the Drive Mechanism and Wheels

Start by checking the drive mechanism and wheels for any debris buildup that could hinder movement. Make sure to lubricate the moving parts regularly to keep everything running smoothly. Also, inspect for signs of wear and tear to prevent breakdowns during cleaning sessions. Regular maintenance of the drive components helps ensure optimal performance and longevity of your pool cleaner drive system components. Additionally, verify that the wheels are properly aligned to avoid uneven wear and improve maneuverability. Monitoring the filtering system can also help maintain the efficiency of your pressure pool cleaner and prevent clogs that might impair its operation.

Check for Debris Buildup

Have you checked the drive mechanism and wheels lately for debris buildup? Debris can hinder your cleaner’s performance and cause unnecessary wear. Before inspecting, ensure you follow safety precautions to avoid accidents or damage. When cleaning, consider these points:

- Remove loose debris like leaves and dirt from wheels and gears.

- Check for any stuck debris that could block movement.

- Inspect for signs of wear or damage on the wheels.

- Clean the drive mechanism with fresh water, avoiding harsh chemicals that could affect pool water chemistry.

- Regular maintenance of the self-watering system can help prevent blockages and ensure consistent performance. Additionally, inspecting for clogged filters can improve overall efficiency and prevent future issues.

Regularly inspecting and clearing debris maintains ideal cleaning performance and prolongs your cleaner’s lifespan. Remember, proper pool water chemistry helps prevent buildup and keeps your equipment running smoothly. Always prioritize safety when handling tools or cleaning parts.

Lubricate Moving Parts Regularly

To keep your pressure pool cleaner operating smoothly, it’s essential to lubricate the moving parts regularly, especially the drive mechanism and wheels. Follow a consistent lubrication schedule to prevent squeaking and ensure smooth movement. Use suitable lubricants, such as silicone spray or a light machine oil, that won’t damage plastic components. Before applying, clean off any dirt or debris to ensure proper lubrication. Focus on the drive shaft, wheels, and any pivot points, rotating parts as needed. Regular lubrication reduces friction, prevents rust, and extends the lifespan of your cleaner. Additionally, monitoring the air quality around your pool area helps maintain a healthy environment for swimmers. Check the manufacturer’s recommendations for specific lubricant types and intervals. Staying on top of this maintenance task helps your pressure pool cleaner operate efficiently and reduces the risk of breakdowns.

Examine for Wear and Tear

Regularly inspecting the drive mechanism and wheels for signs of wear and damage is essential to keeping your pressure pool cleaner functioning effectively. Look for cracks, chips, or warping on the wheels, which can hinder movement. Check the pressure hose for leaks or blockages that reduce suction power. Pay close attention to nozzle wear, as worn nozzles can decrease cleaning efficiency.

You should also:

- Replace wheels showing significant wear or damage.

- Ensure the pressure hose is free of cracks or leaks.

- Replace nozzles if they appear worn or blocked.

- Test the drive mechanism for smooth operation, addressing any stiffness or wobbling.

Addressing these issues promptly helps maintain peak performance and extends your cleaner’s lifespan.

Lubricate Moving Parts as Needed

Lubricating moving parts when necessary keeps your pressure pool cleaner running smoothly and prevents unnecessary wear. Check the manufacturer’s guidelines for lubrication frequency—typically every few months or when you notice stiffness. Use suitable lubricants, such as silicone spray or waterproof grease, to guarantee compatibility with pool components. To help visualize, here’s a quick overview:

| Part | Lubrication Frequency | Suitable Lubricants |

|---|---|---|

| Wheel Bearings | Every 3-4 months | Silicone spray |

| Drive Shaft | As needed | Waterproof grease |

| Propeller | Every few months | Silicone or light oil |

| O-rings & Seals | When dry or cracked | Silicone lubricant |

| Gears | Annually | Grease specified by manufacturer |

Remove and Clean the Skimmer and Suction Fittings

Start by inspecting the skimmer and suction fittings for debris or blockages that can hinder water flow. Remove any debris you find, then clean and flush the fittings thoroughly to prevent buildup. While you’re at it, check for leaks or damage that could affect the cleaner’s performance.

Inspect and Remove Debris

To guarantee your pressure pool cleaner works efficiently, you need to inspect and remove debris from the skimmer and suction fittings. Blockages can hinder circulation, affecting pool chemical balance and increasing algae risk. Regularly checking these areas helps maintain ideal cleaning performance. Here are key steps to follow:

- Turn off the pump before inspecting.

- Remove debris like leaves or twigs from skimmer baskets.

- Clear out any obstructions from suction fittings.

- Rinse fittings with a hose to prevent buildup.

Removing debris ensures proper water flow, which supports balanced chemicals and algae prevention. Keeping these fittings clean reduces strain on your pressure cleaner and prolongs its lifespan. Make this inspection routine part of your maintenance to keep your pool sparkling and healthy.

Clean and Flush Fittings

Regularly cleaning and flushing your skimmer and suction fittings guarantees they stay free of dirt and buildup that can restrict water flow. To maintain ideal performance, incorporate this task into your maintenance scheduling, ensuring it’s done at least every few months. Remove the fittings carefully, then scrub out any debris or algae using a brush. Rinse thoroughly with clean water, paying attention to remove any obstructions. Flushing the fittings with water helps clear out lingering dirt and restores proper flow. Keep an eye on your water chemistry, as imbalanced levels can cause buildup or corrosion. Consistent cleaning prevents clogs and maintains efficient circulation, reducing strain on your pool equipment. Proper maintenance of fittings ultimately prolongs their lifespan and keeps your pressure pool cleaner working at its best.

Check for Leaks or Damage

Since leaks or damage in your skimmer and suction fittings can impair your pool cleaner’s performance, it’s essential to inspect them regularly. Start by removing and cleaning these fittings to spot cracks or worn seals. Confirm the fittings are tightly connected and check for any signs of leaks, which can affect the pool’s chemical balance and water temperature monitoring.

Here are four key steps:

- Turn off the pump before removing fittings.

- Clean debris and buildup from the fittings.

- Examine for cracks or damaged seals.

- Replace any damaged parts immediately.

Keeping these fittings in top condition helps maintain proper water flow, ensuring your pool cleaner works efficiently and your pool remains balanced and safe.

Store the Cleaner Properly During Off-Season

When the swimming season ends, properly storing your pressure pool cleaner is essential to keep it in good condition for next year. Follow these storage tips to protect your investment during seasonal maintenance. First, clean the cleaner thoroughly to remove debris, dirt, and any residual chemicals. Rinse all parts with fresh water and let them dry completely to prevent mold and corrosion. Store the cleaner in a cool, dry place away from direct sunlight, which can degrade plastic components. Coil hoses loosely to avoid kinks and damage. Keep the unit out of extreme temperatures to prevent warping or cracking. Proper storage guarantees your pressure pool cleaner stays in top shape, making start-up easier and more efficient when the swimming season begins again.

Replace Worn or Damaged Components Promptly

Replacing worn or damaged components promptly is essential to keep your pressure pool cleaner functioning efficiently. When you catch issues early, you prevent further damage and guarantee peak performance. Regular component replacement not only extends the cleaner’s lifespan but also enhances its cleaning efficiency.

Here are key points to keep in mind:

- Inspect hoses, brushes, and nozzles regularly for signs of wear.

- Replace cracked or brittle parts immediately to prevent leaks.

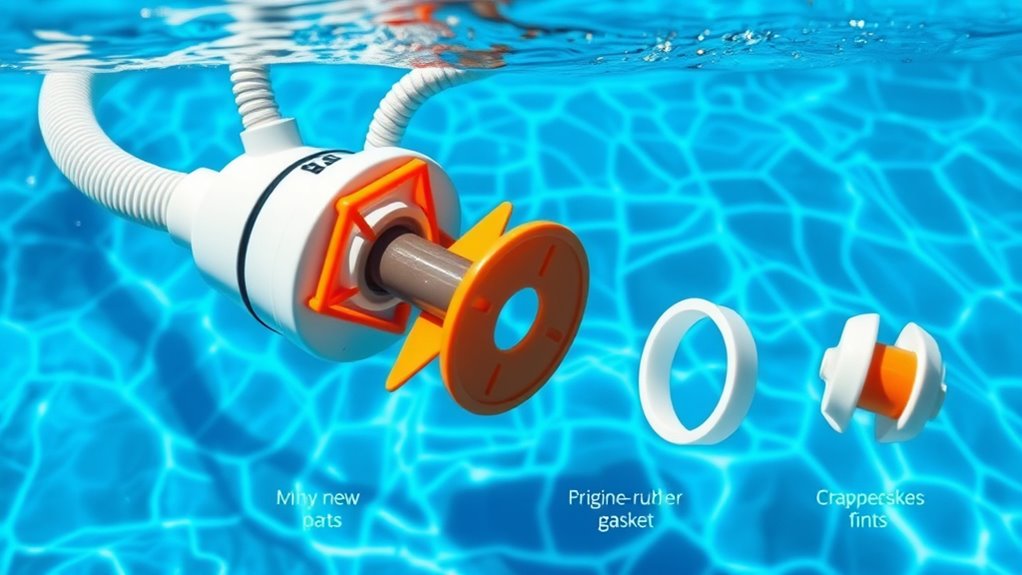

- Check seals and gaskets for damage to maintain proper water flow.

- Use quality replacement parts to ensure durability and effective damage prevention.

Schedule Regular Maintenance Checks

Scheduling regular maintenance checks is crucial to keep your pressure pool cleaner operating at peak efficiency. During these inspections, you should clean filters and brushes with appropriate cleaning solutions to remove dirt and debris. Check hoses and connections for leaks or damage, replacing parts as needed. Proper storage tips are essential; store your cleaner in a cool, dry place away from direct sunlight to prevent deterioration. Regular checks help identify worn components early, saving you money and hassle down the line. Incorporate cleaning solutions designed for pool equipment to ensure thorough cleaning without damaging parts. Establishing a maintenance schedule keeps your pressure pool cleaner running smoothly, extending its lifespan and ensuring your pool stays sparkling clean all season long.

Frequently Asked Questions

How Often Should I Perform Routine Maintenance on My Pressure Pool Cleaner?

You should perform routine maintenance on your pressure pool cleaner based on your maintenance schedule, which typically involves checking it weekly. Cleaning frequency depends on usage and water conditions, but generally, you should inspect and clean filters and brushes at least once a month. Regularly removing debris and checking for wear helps guarantee peak performance. Staying consistent with maintenance keeps your cleaner working efficiently and extends its lifespan.

Can I Use Chemical Cleaners to Sanitize the Cleaner’S Components?

Did you know that over 80% of pool owners prefer chemical cleaning for convenience? You can use chemical cleaners to sanitize your pressure pool cleaner’s components, but do so carefully. Avoid harsh chemicals that could damage parts. Instead, opt for pool-safe sanitizers and follow manufacturer instructions. Proper chemical cleaning helps prevent mold and bacteria buildup while keeping your cleaner in top shape, ensuring efficient performance and extending its lifespan.

What Precautions Should I Take When Handling Electrical Parts of the Cleaner?

When handling electrical parts of your pressure pool cleaner, prioritize electrical safety by turning off the power before touching any components. Always wear protective gear like gloves and insulated tools to prevent shocks. Keep the electrical parts dry and avoid working in wet conditions. Regularly inspect cords and connections for damage. Taking these precautions guarantees your safety and helps keep your cleaner functioning properly.

Is It Necessary to Replace Parts Even if the Cleaner Appears to Function Properly?

You might think your pressure pool cleaner doesn’t need part replacement if it functions properly, but wear and tear can cause unseen issues. Regularly inspect components, even if it works fine, because small damages can worsen over time. Replacing worn parts proactively can prevent breakdowns and extend your cleaner’s lifespan. Trust your judgment, but don’t overlook the importance of routine maintenance and timely part replacement to keep your cleaner in top shape.

How Do I Troubleshoot if the Cleaner Is Not Moving or Cleaning Effectively?

If your pressure pool cleaner isn’t moving or cleaning effectively, start troubleshooting by checking for pool hose leaks, which can reduce pressure. Listen for unusual motor noise, as it might indicate a motor issue. Make sure all connections are tight and hoses are free of kinks. Inspect for debris blocking the wheels or brushes. Address any leaks or noise problems promptly to restore proper function and keep your pool spotless.

Conclusion

Maintaining your pressure pool cleaner keeps your pool pristine and your weekends stress-free. Think of it as your pool’s heartbeat—steady, reliable, and essential. When you neglect it, debris and wear take over, turning smooth operation into a tangled mess. But with regular care, you’ll enjoy clear waters and effortless cleaning. Keep it running like new, and your pool will welcome you with sparkling, inviting waters—ready for relaxing swims, not costly repairs.