To guarantee steam table safety, you should regularly clean and maintain your equipment. Daily, turn off the unit, drain water, scrub with mild detergent, and descale probes. Weekly, inspect drain lines and perform descaling to prevent buildup. Monitor water levels and food temperatures, aiming for 140°F (60°C) or higher. Always be cautious of obstructions and maintain cleanliness. By following these best practices, you'll keep your steam table efficient and safe for food service. Discover more essential tips on maintenance techniques.

Key Takeaways

- Perform daily cleaning by scrubbing wells, descaling probes, and ensuring no water stands to maintain hygiene and prevent mineral buildup.

- Preheat the steam table before use and monitor water levels to ensure consistent heating and food safety.

- Regularly check and clear drain lines of debris to prevent blockages and backups in the drainage system.

- Use approved cleaning agents for routine maintenance to protect stainless steel and extend equipment lifespan.

- Maintain food temperatures at 140°F (60°C) or higher, using lids or heat lamps for dense items to ensure safety.

Importance of Regular Cleaning

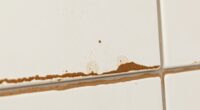

When you neglect regular cleaning of your steam tables, you're not just risking food safety; you're also shortening the equipment's lifespan.

Regular steam table cleaning is essential to prevent bacteria and food residue buildup, which can compromise hygiene standards. By cleaning food wells and surfaces daily, you maintain ideal performance and prevent corrosion, ensuring your unit lasts longer.

If you let mineral buildup from water accumulate, you'll notice increased energy consumption, leading to higher operational costs.

Use non-abrasive sponges and mild detergents to protect your stainless steel finish and avoid damaging heating elements.

A well-maintained steam table not only enhances food safety but also supports efficient operation, minimizing downtime and saving you money in the long run. Additionally, ensuring proper airflow around your steam table can further enhance its performance and longevity.

Daily Cleaning Procedures

To keep your steam table operating efficiently, you should implement a daily cleaning routine that starts with turning off the thermostat and allowing the unit to cool.

Once cooled, drain the water and scrub the wells with mild detergent to remove any residue.

Once the steam table has cooled, drain the water and scrub the wells with a mild detergent to eliminate residue.

Don't forget to lightly clean the heating elements to eliminate calcium and lime buildup.

If your steam table has high and low water probes, descaling them is essential for ideal performance.

After scrubbing, rinse the steam table thoroughly and dry it to prevent mineral buildup and liquid degradation. Regular cleaning can also improve indoor air quality, which is crucial for maintaining a healthy environment in food service areas.

Weekly Maintenance Tasks

Each week, you need to focus on descaling your steam table to keep it running efficiently. Make sure to inspect and clear the drain lines to prevent any blockages that could disrupt performance. Regular attention to these tasks can save you from costly repairs down the line. Additionally, consider incorporating advanced cleaning technology to enhance the overall maintenance process.

Descaling Procedures

Descaling procedures are essential for keeping your steam table in top condition, as manufacturers often recommend performing this task at least weekly.

To guarantee effective cleaning, follow these steps:

- Use a descaling agent approved for stainless steel to safely remove scale deposits.

- Rinse the well assembly thoroughly with a vinegar and water mixture to neutralize any cleaner residue.

- Avoid highly caustic cleaners, acids, or ammonia, as these can corrode your unit.

- Ascertain no water stands in the wells after cleaning to prevent mineral buildup.

Additionally, regular maintenance practices, such as properly seasoned wood, can significantly enhance the longevity and efficiency of equipment like steam tables.

Drain Inspection

Regular drain inspections are crucial for maintaining the efficiency of your steam table. Routinely check drain lines for any obstructions that could hinder water flow and cause backups. If you neglect this weekly task, you risk costly repairs and downtime.

During your inspection, verify that no drain lines have become loose or disconnected, as this can lead to leaks and sanitation issues. Confirm that all drain connections are tight and secure, since loose connections may compromise the unit's functionality.

Regular checks are essential not only for your steam table's proper operation but also for food safety, as stagnant water can create hazards. Additionally, maintaining air quality indicators in your kitchen environment can help ensure a safe food preparation space. Stay proactive, and keep your steam table running smoothly!

Descaling for Longevity

Regular descaling is essential for keeping your steam table running efficiently. Manufacturers often recommend doing it once a week, especially if you have hard water. Additionally, implementing regular maintenance practices can enhance the longevity and performance of your equipment.

Importance of Regular Descaling

Regular descaling is essential for maintaining ideal performance and avoiding costly repairs. Here's why you should prioritize this maintenance task:

- It removes harmful mineral buildup, enhancing energy efficiency.

- It prevents heating elements from working harder than necessary.

- It guarantees consistent temperature maintenance for food safety.

- It extends the lifespan of your steam table.

Using approved descaling agents specifically for stainless steel is important, as improper cleaning can cause corrosion. Additionally, maintaining equipment properly can reduce long-term costs associated with repairs and replacements.

By incorporating regular descaling into your routine, you not only protect your equipment but also maintain the quality of the food you serve.

Don't overlook this fundamental maintenance step!

Recommended Descaling Frequency

To guarantee your steam table operates efficiently and lasts as long as possible, aim to descale it at least once a week. If you're in an area with hard water, you might need to increase your descaling frequency to combat mineral buildup. Regular maintenance visits can help identify issues early, but neglecting to descale can lead to higher energy costs and a shorter service life. Scale deposits can severely impact your unit's efficiency and cause damage to heating elements. Additionally, consistent descaling can prevent corrosion damage that might arise from prolonged neglect.

| Issue | Consequence | Solution |

|---|---|---|

| Scale buildup | Increased energy costs | Weekly descaling |

| Reduced efficiency | Shorter service life | Regular maintenance visits |

| Corrosion damage | Costly repairs | Consistent descaling |

Safe Descaling Practices

While maintaining your steam table, safe descaling practices are essential for ensuring longevity and efficiency.

Regular descaling helps prevent scale buildup, which can lead to increased energy consumption and decreased performance. Here are some key points to follow:

- Descale weekly, especially if your local water quality is poor.

- Use chemicals to clean that are specifically approved for stainless steel to avoid corrosion.

- Thoroughly rinse the well assembly after descaling to eliminate any cleaner residue.

Neglecting these practices can shorten your steam table's lifespan and impact food service operations. Additionally, implementing optimal comfort in your kitchen environment can enhance overall efficiency and productivity.

Safe Operating Practices

Guaranteeing safe operating practices for steam tables is essential for maintaining food safety and preventing contamination. Always preheat the steam table to the desired temperature before adding food; this helps avoid unsafe temperature drops that can promote bacterial growth.

Regularly monitor water levels to guarantee consistent heating and protect the heating elements from damage. Use proper cleaning procedures by scrubbing the wells daily with a mild detergent and non-abrasive pads.

Make sure all food placed in the steam table is fully cooked beforehand, as these units are meant to keep food warm, not cook it. Finally, train your staff on the importance of these protocols to enhance food safety and guarantee successful maintenance visits. Additionally, ensure that any staff handling food are aware of essential oils for antimicrobial properties to maintain a clean environment.

Gas vs. Electric Steam Tables

When choosing between gas and electric steam tables, it's important to evaluate cost and energy efficiency.

Gas models might save you money upfront, especially in areas with high electricity rates, while electric models could lower your energy bills over time with their efficiency.

Think about your establishment's specific needs and utility costs to make the best choice.

Cost Considerations

Choosing between gas and electric steam tables involves a careful look at costs, both upfront and ongoing. Here are some key cost considerations to keep in mind:

- Upfront Costs: Electric models usually cost more initially, while gas tables are generally cheaper to purchase.

- Operating Costs: Monthly expenses can differ greatly based on local utility rates; electric units may be more costly if electricity prices are high.

- Installation Costs: Gas tables might need extra plumbing and ventilation; electric models could require electrical upgrades.

- Long-term Savings: Electric steam tables can offer energy efficiency, reducing consumption by 10-15%, leading to lower bills over time.

Evaluate these factors to determine the best option for your needs while keeping an eye on your budget!

Energy Efficiency

After weighing the cost considerations for gas and electric steam tables, energy efficiency becomes a significant factor in your decision.

Generally, electric steam tables are more energy-efficient due to precise temperature control and superior insulation. However, if your electrical system isn't properly configured, energy consumption can spike, undermining efficiency.

Gas models heat up quickly, making them suitable for mobile setups, but fluctuating gas prices can lead to higher operational costs.

To keep both types running efficiently, regular planned maintenance visits are essential. Descaling and cleaning guarantee peak performance, preventing unnecessary energy waste and high bills.

Ultimately, consider local energy costs and resource availability when choosing the best option for your needs.

Temperature Management Techniques

To guarantee food safety in a steam table, it's crucial to manage temperatures effectively from the start.

Foodservice operators should implement the following temperature management techniques:

- Preheat the steam table to the desired temperature before adding food to avoid unsafe drops.

- Keep the maximum water level in the wells at one and a quarter inches to facilitate proper heating.

- Regularly check food temperatures with a food thermometer, aiming for 140°F (60°C) or higher.

- Use lids or heat lamps for dense items to maintain warmth and prevent drying.

Drain Maintenance Best Practices

Maintaining the drains in your steam table is essential for smooth operations, as blockages can lead to frustrating backups and potential food safety issues. Routinely check drain lines for obstructions to guarantee effective drainage.

Daily, clear debris and food particles from the drains, since even small blockages can cause significant problems. Regularly inspect connections to make certain no drain lines have loosened or disconnected, which could lead to leaks.

Schedule weekly maintenance checks specifically for the drain system to catch issues early. When you clean the drains, use a proper cleaning solution and tools, steering clear of harsh chemicals that could corrode pipes and result in future failures.

Prioritizing drain maintenance keeps your steam table running efficiently.

Staff Training and Best Practices

While ensuring your steam table operates efficiently, it's crucial to prioritize staff training on best practices. Proper training not only enhances safety but also improves the overall performance of your equipment.

Ensuring your steam table operates efficiently starts with prioritizing staff training on best practices for safety and performance.

Here are key areas to focus on:

- Clean steam tables daily, targeting all food wells, surfaces, and drains.

- Preheat the steam table to the desired temperature before adding food to prevent unsafe temperature drops.

- Monitor water levels closely; operating without enough water can damage the equipment.

- Educate staff on regular descaling to avoid mineral buildup and improve energy efficiency.

Troubleshooting Common Issues

How can you quickly identify and resolve common issues with your steam table? Start by regularly inspecting your commercial steam unit for any signs of wear or damage.

Keep a close eye on water levels—operating without enough can lead to overheating and shorten the unit's lifespan.

Check that the thermostat is calibrated correctly to guarantee food stays at safe temperatures; inaccurate settings can create unsafe conditions.

Also, routinely examine drain lines for blockages, as these can cause backups and unsanitary situations.

Don't forget to schedule planned maintenance visits to tackle potential issues before they escalate.

Frequently Asked Questions

How Do You Maintain Safety on a Steam Table?

To maintain safety on a steam table, you need to guarantee that all food is fully cooked before placing it in the table.

Regularly check food temperatures, keeping them above 140°F.

After each use, clean and sanitize the table to prevent cross-contamination.

Train your staff on proper usage and maintenance protocols.

Finally, inspect the steam table for any signs of wear or damage to avoid malfunctions and guarantee a safe environment.

What Is the Best Way to Clean a Steam Table?

To clean a steam table effectively, start by turning off the thermostat and letting it cool down.

Drain the water, then scrub the wells using a mild detergent and a non-steel wool pad to prevent damage.

Lightly scrub the heating element to remove any buildup, and use a de-scaling agent weekly for tough deposits.

Rinse everything thoroughly to avoid residue, and check drain lines regularly to keep them clear and functioning properly.

What Are the Best Practices for Steam Table?

When it comes to steam tables, you've got to strike while the iron's hot! Best practices include cleaning daily with mild detergent and avoiding abrasive sponges to protect surfaces.

Regularly check water levels to guarantee proper heating and prevent damage. Weekly descaling keeps it efficient, while planned maintenance checks catch any wear early.

Finally, training your staff on proper usage and cleaning protocols will keep everything running smoothly and safely.

What Is the Best Cleaning Agent for a Steam Table?

The best cleaning agent for your steam table's surface is a mild detergent specifically designed for stainless steel. It effectively removes dirt without damaging the finish.

Avoid abrasive sponges and harsh chemicals, as they can cause corrosion. For stubborn grease, mix mild dish soap with warm water and use a soft cloth.

Always rinse and dry thoroughly afterward to prevent mineral buildup and keep your steam table in top shape for longer.

Conclusion

Keeping your steam table clean and well-maintained is like tuning a fine instrument; it guarantees everything runs smoothly and harmoniously. Just as musicians regularly polish their violins, you should commit to daily and weekly cleaning routines. With proper temperature management and regular descaling, your steam table will perform at its best, serving delicious meals safely. Remember, a clean steam table not only extends its life but also enhances the dining experience for everyone who enjoys your culinary creations.